As Liberty continues to invest in improvements and upgrades to the Pine Bluff water system, one of the biggest changes will be the implementation of a supervisory control and data acquisition (SCADA) system.

Helping lead this transition is Operations Manager Roman Diaz, who has been with the Pine Bluff team for nearly two months. Diaz transferred to Pine Bluff after working in Apple Valley, California, in Liberty’s West Region. While there, he progressed from working in pipeline, distribution, and production to interim supervisory/ manager roles.

“My position entails basically the day-to-day operations of the (water) system,” he says. “That includes water in Pine Bluff, water and sewer in White Hall, and water in Woodson and Hensley.”

While it’s easy to take clean tap water for granted, the process in delivering it can be complex.

Water is pumped from wells to the water treatment plants, where it is filtered and treated. From there, the water flows into storage tanks and standpipes before being pushed out into the residential and commercial water system.

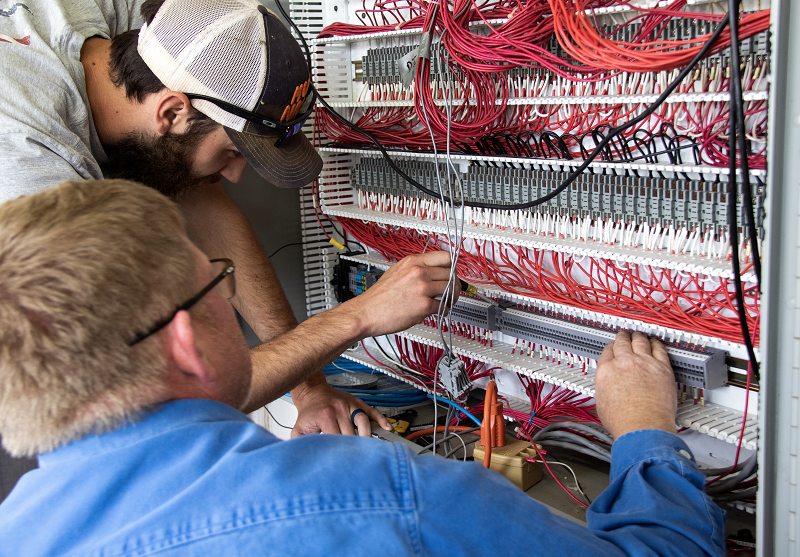

Installing the SCADA system will help to streamline this process, says Diaz.

“SCADA is used not only in the water and wastewater realm, but also in manufacturing plants and a lot of other entities … it’s used for control of your facilities,” he says. “So instead of having people turn wells off and on, doing back washes on filters and manually setting chemical injection rates, it’s all done remotely or via the computer system.

“The value for our customers is that there’s less physical overhead. You don’t have positions where somebody has to stand there and turn knobs. Our employees can be doing other work, such as system improvements and maintenance. And the upgrade is going to help tie all our plants together for a better, more robust system.”

For those who enjoy acronyms, there are a few of them when explaining how SCADA works.

Through a Human Machine Interface (HMI) screen, operators can remotely monitor water pressure, tank levels and well status. The programmable logic controller (PLC) uses “ladder logic” to control what happens.

“Basically, it’s ‘If this, then that,’” says Diaz. “The PLC is like the brain … kind of like how a CPU in your computer works. So if this happens, then that happens. If the pressure were to get to, say, 59.1 psi, then this high-service pump will kick in. Or if the input at a plant is this, then the chemicals are added for that level.”

But at the end of the day, SCADA serves a simple – but highly important – purpose.

“Our goal here is to provide safe, high-quality water at a fair price,” says Diaz. “The positive aspect of Liberty’s capital investment is that it’s all about the customer and providing water that is sustainable.”